Below is a small handfull of modifications

I have made over the years to make boats more to my

liking for general paddling and self-support. Most of

this work was done on boats which are now outdated.

I leave this page up for the purpose of sharing and

documenting my experiences only. I do not recommend

any of these or similar modifications to any kayak,

old or modern. They may cause your kayak to become unsafe

causing serious injury or death. If you make

any of these or similar modifications, to any kayak,

do so at your own risk!

Miscellaneous kayak mods

Below are a few modifications I

made to the Riot Magnum outfitting circa the inception

of the Magnum.

|

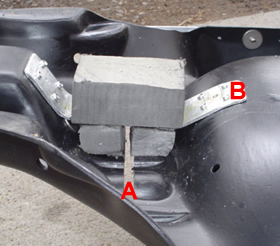

The weakest

part of the seat was further weakened with the factory

backband slot (A). This also happens to line up

with the weakest area of cockpit rim. To counter,

I spaned the slot from under the seat with a 2"

wide piece of aluminum (B); fastened it to the seat

with 8 rivets; then braced it with foam that rests

on the hull. Being that I no longer use the slot

(A), I could have done something else here that

was more effective. As shown, the gains were likely

very minimal. |

|

Stock, the factory

seat moved side to side enough (1.5" each

way) that I could feel it while paddling, especially

bracing. And the gap between the top of the seat

& underside of the cockpit rim created a flex

point in its most vulnerable spot. The foam on

the top (A) takes out most of the flex while the

foam between seat & sidewall (B) nearly eliminates

side to side movement. This simple & quick

little fix made the boat feel noticably better

while paddling. Excellent returns!

PS:

Gluing hip pads in produces cleaner results than

duct tape but, in an attempt to minimize my chemical

body burdon as much as possible, I quit using

adhesives. Hippie chrome works & is much faster.

|

|

Here are 3 very

simple & easy mods. To facilitate egress,

I chamfered both sides of the pillar (A). The

holes in the bulkheads foam (B) adds a little

shock absorbtion. (C) is a bungee cord water bottle

holder. I used a plastic tube from a ball point

pen to keep the bungee from pullling through the

foam. Here's how I did it: poked

hole in foam 3" from edge with phillips head

screwdriver; pulled it out; inserted pen tube

over screwdriver & pushed it in hole; pulled

out screwdriver & run bungee through. |

|

The

original Riot backband adjustment system creates

unnecessary friction. Its geometry also wants

to naturally pull the band downward rather than

forward. The way it is configured in the above

photo, the band is pulled in a straight line and

with no friction. Getting this band tight to your

back is also far easier and faster than with the

conventional ratchet system. To tighten, I simply

lean forward and pull rather than ratchet.

After numerous configurations,

this is by far the best I have come up with. I

left the original strap and ratchet in place for

a back-up. It can be made operational in one to

two minutes. The backband is a modified Riot band...the

same one shown here.

Tightening is done by pulling on the whiteish

colored toggles seen hanging below the thigh braces.

The ratchet straps run through toothed spring

loaded pieces salvaged from the older Riot thigh

strap system (like a ratchet without the ratchet

lever). These are fastened to the existing holes

used for the thigh brace adjustment and reinforced

with aluminum plates.

|

| |

|

|

Here's an old thermo

formed seat I cut the back out of (indicated by

the red arrows) and reinforced with aluminum.

The aluminum against the existing pillar pocket

(A) was welded to a 3" wide piece of aluminum

which was also part of the 1.25" wide band

(B) that wrapped around the back of the seat.

This band assembly was then attached to the seat

with thirteen rivets as can be seen in the top

2 pics. Finally, (A) was attached to the existing

pillar pocket via one 1”x1" aluminum

angle (indicated by green arrow) per side and

a total of ten 1/8" Ø button head

screws.

Cutting the seat

like this severely weakened its structural integrity.

With the aluminum bracing, it recovered an estimated

85% of its original integrity. I justified the

15% loss due to this particular kayaks unusually

high shell strength.

For this seat and

boat, this mod worked well. It greatly improved

the access and allowed some of the weight to be

carried lower and closer to my butt.

|

|

|

Below are some modifications I did

to a Dagger CFS including the installation of an old

roto molded Wave Sport X seat and building a new backband

from an older Pyranha band.

Stock, the CFS was one of the more

difficult boats to load I have used. After these mods,

it was amongst the easiest of pillared kayaks. The boat

also lost two pounds in the process and retained most

of its structural integrity... and possibly gained in

some areas. Prior to this swap, I cut the back out of

the stock seat similarly to the photos above. However,

due to this seat's configuration, the overall gains

were so small, I ended up throwing it in the trash (recycling

center wouldn’t take it).

| I

cut the top part of the X pillar pocket out (A)

to accomodate the CFS pillar (B). To provide extra

pillar/seat connection, I extended this pocket towards

the stern 3" with aluminum (E). This same piece

of aluminum overlaps the seat 3" per side (F)

and is attached with 20 rivets. For additional lateral

stability, I also extended the pocket vertically

(D) to the underside of the cockpit rim & ran

a 1/4' Ø bolt through this & the pillar.

The nut & head were covered with minicell (C)

to prevent snagging or undue wear to my drybags.

To further facilitate ease of loading, the minicell

was chamfered with a rasp (B) (C). |

|

| The padded part of

this backband was salvaged from an old Pyranha.

I made the rest including the aluminum brackets

that attach it to the seat. The red ball inside

the circled area is the loose end of the adjustment

strap which extends just past my hip when pulled.

Once in the boat, I reach behind, grab the ball,

pull to tighten, drop it behind & put on my

skirt. Simple, light, and fast. |

|

| Ready to load. This

shows the backband folded out of the way...a process

easily done in 3 seconds by loosening the metal

cam buckle & unhooking the bungee cords. The

red ball on the loose end of the adjustment strap

can be seen lying in the center of the seat. I salvaged

this ball from a rescue PFD quick release. |

|

| (A) indicates the

metal cam buckle and (B) the extra long adjustment

strap. The red ball on the end of this strap is

lying in the stern and not visible in this photo.

|

|

| This is the hook

the backband bungee cords attach to. It's shaped

like a T with the top part held to the cockpit rim

with four rivets. The slot indicated by the red

arrows allowed the aluminum to bend more easily

without breaking. |

|

| Here's the front

pillar connection. I just notched the top area of

the X seat (A) enough (2") to accomadate the

plastic CFS pillar (B), inserted solid plastic spacers

inside (indicated by red arrows) & bolted it

together with one 1/4" Ø bolt. Though

not sharp, the nut sticks out enough to have cut

my ankle in a hasty exit. It should have been covered

with chamfered minicell or something similar. |

|

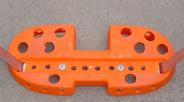

Shaving ounces

The amount which can be saved by

swiss cheesing depends on each particular boat. The

more plastic there is in the outfitting, the more that

can be saved. That said, there's usually no single mod

that will justify the time. It's the culmination

of many small mods that makes the difference. And

even then, it would be rare to save a pound by drilling

only. Removing the excess aluminum from the bulkhead

(losing adjustability for taller folks) and modifying

backbands can reduce the weight further.

Most of the time, you can expect

to lose some strength to any piece you drill holes in.

To what degree depends on the number of holes, placement,

and configuration.

|

|

|

|

|

|

|

An aluminum bulkhead

I made for a Disco. |

top

|